Add to Cart

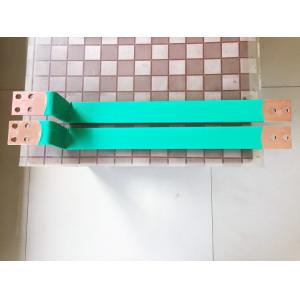

Tin Plated Copper Busbar for Electrical Box and Transformer

The lubricant, residual acid, residual water, etc. remaining on the surface of the copper busbar during the drawing process of the copper busbar will also directly or indirectly affect the surface quality of the copper busbar. A better lubricant has good lubricity, and the residual capacity on the surface of the copper busbar is the source of discoloration or corrosion marks on the surface of the copper busbar.

The role of the process lubricant is to reduce friction; the second is to ensure and improve the surface quality of the processed material; the third is to prevent the metal from sticking to the mold; the fourth is to cool down.

Factors affecting the smooth surface of copper busbar Compared with other metals, copper has good corrosion resistance, but chemical changes will still occur in high temperature, humidity, acid fog and other environments, resulting in surface discoloration. In the process of copper busbar production, storage and transportation, these unfavorable environmental conditions exist to varying degrees, which will have a certain impact on the surface quality.

Product parameters

| Material | Non-ferrous alloy material like carbon steel,stainless steel,galvanized steel,aluminum,copper,brass,etc |

| Surface Finish | All kinds of surface treatment are available like chrome plating,zinc plating,nick plating,powder coating,e-coating,dip coating,mirror polishing,etc. |

| Application | Electronic/Appliance/Auto/Industrial equipment metal stamping hardware parts |

| Processing | Our process includes tooling fabrication,stamping,deep drawing,punching, spinning,laser cutting,bending,seamless welding,machining and assembly |

| Quality Control | Liability System and Periodical QC on line every hour |

| Main Market | USA/Germany/Canada/Italy/United Kingdom/Australia/Pakistan/French,etc |